The borescope inspection procedure mainly includes the following four aspects: internal combustion engine carbon detection, shock absorber spring inspection, gear box inspection, hollow shaft inspection. With the industrial borescope, how to do each one of these inspections? Firstly, we should know how borescope is defined, what it is used for and how it works.

Contents

Borescope and borescope inspection procedure

A borescope (occasionally called a boroscope, though this spelling is nonstandard) is an optical instrument designed to assist visual inspection of narrow, difficult-to-reach positions, consisting of a rigid or flexible tube with an eyepiece or display on one end, an objective lens or camera on the other, linked together by an optical or electrical system in between. The optical system in some instances is accompanied by (typically fiberoptic) illumination to enhance brightness and contrast. An internal image of the illuminated object is formed by the objective lens and magnified by the eyepiece which presents it to the viewer’s eye.

Sometimes it’s hard to have a clear look inside machine details or inside pipes, where human’s eyes can not reach to. A quality borescope camera (borescope inspection procedure) will help you to look round corners. Making it possible to capture video or still images deep within equipment, engines and other dark spaces.

What borescope inspection procedure consists of:

Internal combustion engine carbon detection:

For diesel engines, Shodensha industrial borescope can be used for carbon detection. Diesel engine diesel engine exhaust valve if there is carbon, it will reduce the effective internal combustion engine power, resulting in high fuel consumption. The use of industrial borescope to avoid the tedious disassembly of the traditional diesel engine operation, just need to insert the endoscope into the cylinder can be checked, the entire operation is really easy and simple.

Spring suspension inspection:

In the railway repair regulations and factory repair procedures, are referred to the inspection requirements of the spring shock, the specific requirements of the inspection cracks, wear and other conditions, and then according to the maintenance procedures for welding. The traditional inspection methods often require the spring to be disassembled, and the industrial endoscope to accomplish this task, simply send the camera probe to the spring part to be detected, to be able to observe the internal spring cracks, as well as the status of the top of the spring , to avoid incidents insulted from the disassembly of the workload and to avoid economic costs.

Hollow shaft/pipe inspection:

During the operation of electrified high-speed trains, if the hollow shaft is found by ultrasonic testing equipment to be damaged, corroded, worn, and other suspicious parts, the industrial borescope may be used to probe into the interior of the hollow shaft for further double check so that the borescope can be used Microscopic observation of the magnifying effect of the microscope to find cracks. Similarly, inspectors can also use the industrial borescope image processing system to shoot the test video, record the specific status of the hollow shaft so that defects can be re-examined by the computer later to ensure that the test results more accurately.

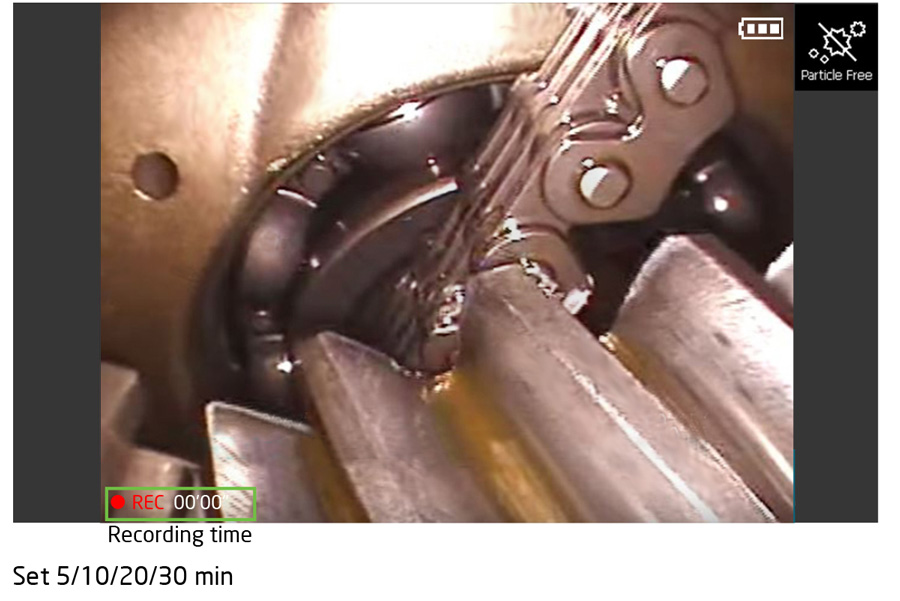

Gearbox inspection:

This is a popular part of the borescope inspection procedure. In the normal operation and running cycle of the locomotive, the gearbox of the traction gearbox is worn and badly mated. It is a common problem that the gearbox can even be scrapped and derailed if it is not detected and handled properly. The use of industrial borescope can be easily completed gear box inspection, the specific operation of the borescope can be simply bend the guide tube into the gear through the oil port observation into the gear box inside, you can see very intuitive The performance of gear inside the gear case and gear box at the bottom of the presence of foreign matter, but also can use the industrial borescope image recording function for shooting archive for further troubleshooting, or for future reference.

How to proceed borescope inspection procedure?

Today remote visual inspection is getting more and more popular throughout the world. But sometimes technicians hesitate to use inspection camera or proceed borescope inspection procedure because they are not sure if they need any special training or skills to work with a borescope. However inspections with such devices in the most of cases do not require any special knowledge or skills. However, there are some basic rules technicians need to follow.

Why choose us – Shodensha for quality but cheap borescope?

As a pioneer in supplying of microscope and microscope products, borescopes, industrial borescopes, we are still making continuous efforts to increasingly improve product quality, technical improvements in many types of products to serve our important needs customers. To us, it’s not just work – we take pride in the products we deliver. We encourage each other to achieve excellence and aren’t satisfied until our services meet our own personal high standards.

Our borescope inspection procedure products have high quality with all details and accessories made and exported from Japan, one of the most technologically developed nations in the world. We ensure to deliver to our customers convenience as well as best experience and satisfaction when working with us buying products from us!

In the future, we will make more efforts, with the goal of serving and bringing maximum satisfaction to customers. If you have any questions or inquiries about the product, please contact us. We hope to receive more love and support from our customers.

Contact:

Shodensha Vietnam Co., Ltd.

Address: HCM: 5th Floor, 178/8 Nguyen Van Thuong, Ward 25, Binh Thanh District, HCMC; HN: No.202, Y2 Building, HH04 Block, Viet Hung Urban Area, Giang Bien Ward, Long Bien District, Ha Noi City

Phone:HCM: +84(28)3911-2006; HN: +84(24)3200-3790

Fax: +84(28)3911-2007

Email: info@shodensha.com.vn

Youtube: Shodensha Thailand Co., Ltd. – YouTube