As one of the most important method of non-destructive testing, industrial borescopes are becoming more and more popular in various industries. As an important component of borescope, the probes directly affect the quality of the test results. How to prevent the probe of industrial endoscope from damaging during work? This is a main topic that every inspector concerned. As an 360 Articulation Probe supplier, Shodensha would like to give you some pieces of advice as below.

Contents

- 1 What’s inside a borescope probe?

- 2 Choose the right lens of your 360 articulation probe before Inspection:

- 3 Slowly and carefully operate during inspection

- 4 Timely collect and organize after inspection:

- 5 Usual care and maintenance of 360 articulation probe

- 6 Shodensha – The pioneer in offering Japanese quality borescope camera

What’s inside a borescope probe?

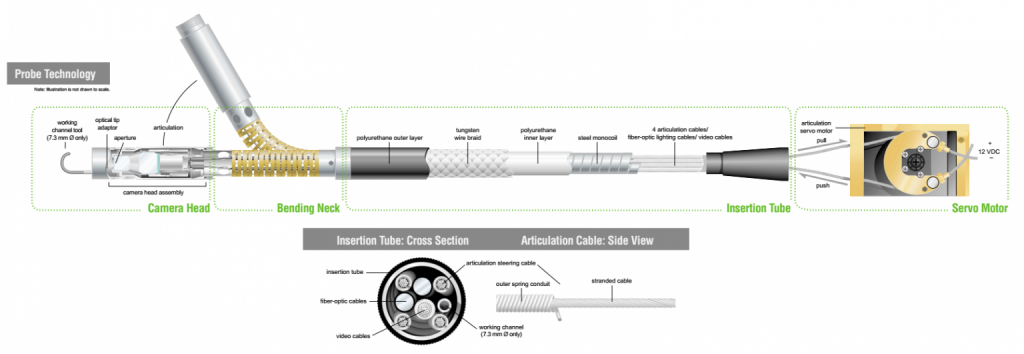

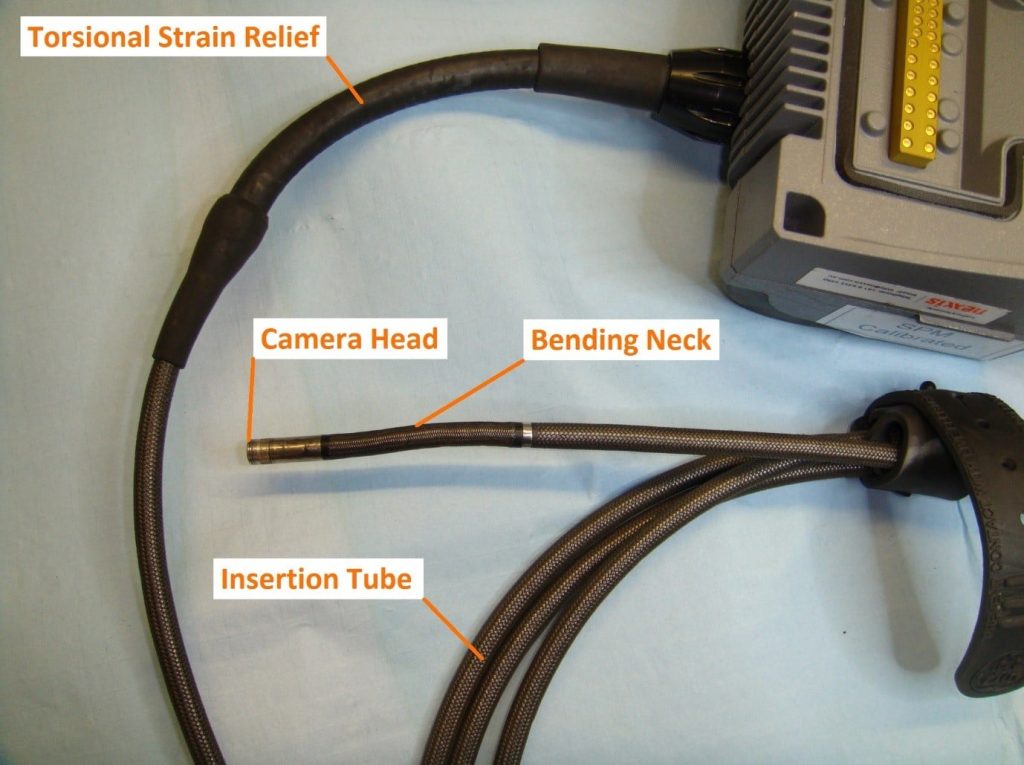

What are the components inside a borescope probe and how do they work together to make your inspections possible? Let’s start with an overall view of a probe, especially 360 articulation probe, so we can lay out the basic segments before delving inside the probe cable.

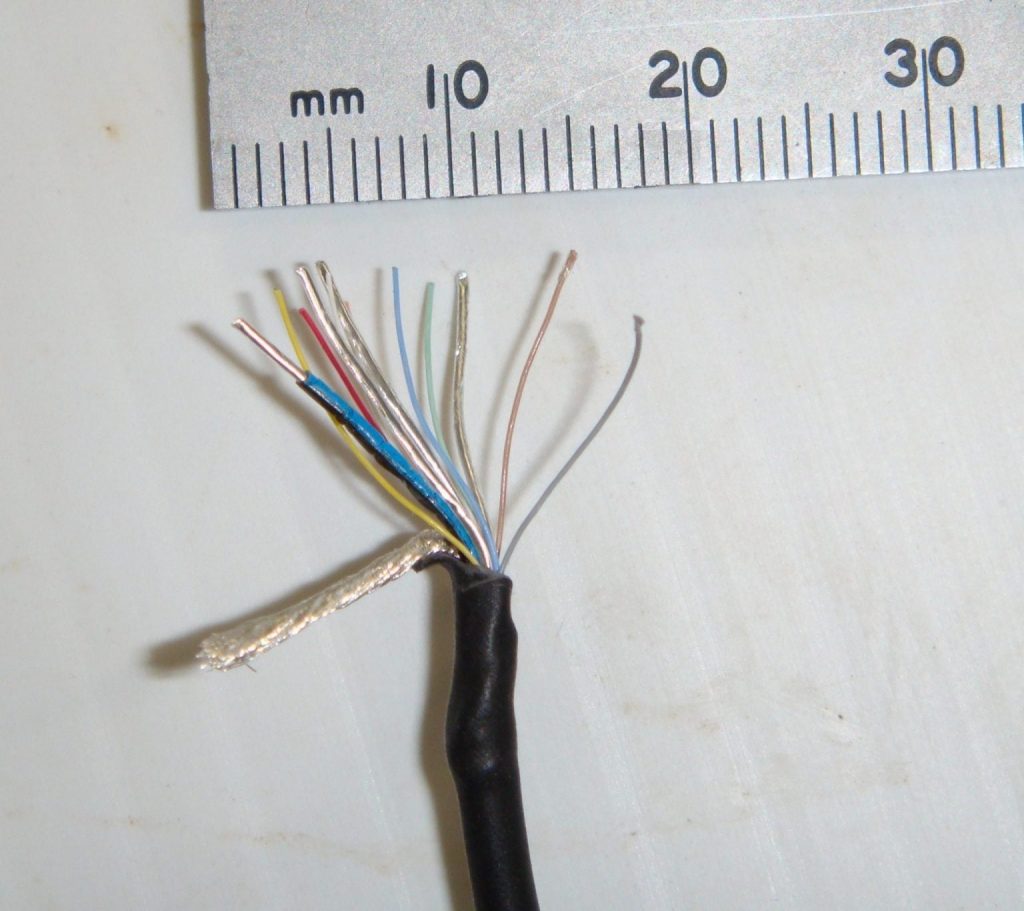

The probe contains an incredible number of miniaturized components. If you took a cross-section of the probe, these are the components you would find:

- More than a dozen electrical conductors (wires), including power, video signals, temperature sensors, LED lighting power for 3D phase measurement, plus other proprietary signals. Beneath its protective insulation, each conductor is only 0.1mm in diameter, which is about the same as a human hair!

- Fiber optic light guide – a bundle of flexible optical glass fibers to transmit high-intensity lighting from a LED inside the handset, all the way to the tip of the probe.

- 360 degree articulation cables – making it a 360 articulation probe, four braided steel wires to control up/down and left/right movement of the bending neck. To fit within the tight space constraints of the probe, each articulation cables is as thin as 0.2mm in diameter, with a 0.6mm diameter protective spring-steel conduit surrounding it!

- Surrounding all of the above are multiple protective layers, including:

- insulation and sheathing on the electrical conductors and fiber optics

- coiled spring steel conduit on the articulation cables

- steel mono coil conduit surrounding the whole probe

- two layers of rugged polyurethane rubber

- braided tungsten wire sheathing

- Additionally, under its braided wolfram sheath, the flexible bending neck is protected from crushing by segmented “vertebrae”, made from a high-strength proprietary alloy.

Choose the right lens of your 360 articulation probe before Inspection:

It is necessary to know the obstacles, burrs and other objects inside the pipe before inspection, then select the appropriate probe and lens to enter the Pipe. At the same time, if you need to replace the lens during inspection, be sure to follow up the correct direction and screwing fasten in order to avoid loose of and damaged lens.

Slowly and carefully operate during inspection

For the larger diameters and longer length of a 360 articulation probe, there is narrow gap for the pipes, it is easy to be blocked when go into the pipes. Therefore, the inspection process should be very careful, the action should be slow and cautious when feeding the probe, to ensure that the probe reaches the specified part smoothly. If there is obvious resistance, stop moving immediately, and then push forward after removing the resistance. Be slow and cautious when exiting, do not pull to avoid damage to the workpiece or the probe. Inspector could use the auxiliary tooling to help the probe reach into right position.

In addition, the pipe or objective should be selected as close as possible to the required detection position, and choose the shortest pipe to enter, minimize the bending times and bending angel. First consider the channel from top to bottom, high to low; prefer to select a wider channel. We recommend you to use the tooling to ensure that the probe is in the correct direction in the pipe channel and through the channel by the method of observation while passing.

Timely collect and organize after inspection:

After finishing inspection, timely storage, clean the probe and put them in the case in order. Put the lens case on the lens, organize the instrument, and place each component in the original cases to protect the 360 articulation probe and make it easy to access next time.

In addition, the maintenance is very important, please make sure to check the 360 articulation probe regularly and remove the faults timely, it could help to extend the life of the probe.

In short, only by taking good care of industrial endoscopes can avoid damage and hurt. To make it play a greater role in the inspection task, creating greater value for production and testing.

Usual care and maintenance of 360 articulation probe

- Check the optical tip for damage or contamination

- Clean all external parts of the optical tip. Use glass cleaner or 70% alcohol-to-water solution and a pointed cotton swab.

- Clean only the internal threads fo the optical tip. The internal optical lens should only be cleaned when trouble-shooting an optical tip that provides poor focus.

- Check the optical tip for damage or contamination

- Clean all external parts of the optical tip. Use glass cleaner or 70% alcohol-to-water solution and a pointed cotton swab.

- Clean only the internal threads fo the optical tip. The internal optical lens should only be cleaned when trouble-shooting an optical tip that provides poor focus.

Shodensha – The pioneer in offering Japanese quality borescope camera

Shodensha Vietnam Co., Ltd. operates with the motto of giving customers peace of mind when using Japanese brand optical microscope products with such high quality and reasonable price. Starting with the supply of microscope and microscope products, we are still making continuous efforts to increasingly improve product quality, technical improvements in many types of products to serve our important needs customers. Now, we also supply our customers with borescopes, industrial endoscopes, borescope probe, 360 articulation probe, and related accessories with high quality from Japan!

Contact:

Shodensha Vietnam Co., Ltd.

Address: HCM: 5th Floor, 178/8 Nguyen Van Thuong, Ward 25, Binh Thanh District, HCMC; HN: No.202, Y2 Building, HH04 Block, Viet Hung Urban Area, Giang Bien Ward, Long Bien District, Ha Noi City

Phone:HCM: +84(28)3911-2006; HN: +84(24)3200-3790

Fax: +84(28)3911-2007

Email: info@shodensha.com.vn

Youtube: Shodensha Thailand Co., Ltd. – YouTube